Robotic process automation: the beginning of a new era

Contents

Robotic process automation: the beginning of a new era

In this article, we’ll talk about robotic process automation (RPA) as one of the key technologies that have led to the Fourth Industrial Revolution. We will also talk about its impact on work, adding to the information we provided in our post titled 2020, the year of automation?

Covid-19 has made the prevalence of telework in Spain rise from 5% to 34%, which means that one out of three workers now works from home. And although the way it was brought about was on an ad hoc basis, experts all agree: telework is here to stay, transforming our workplace. Although as we’ll see further on, this won’t be the first time that it’s happened.

Working from home and the consolidation of the transition to digital will give rise to new work colleagues with whom to take a coffee break: virtual assistants, otherwise known as digital coworkers—a term that is gaining popularity and impact in the sector. According to IDC Research España, their contribution will grow by 35% as more tasks are automated thanks to technology.

From the First to the Fourth Industrial Revolution

A hundred years ago, the workplace was very different from today’s workplace: no computers, Internet or software running every aspect of the business. With the dawn of the new century, we saw the early days of the Internet and email connecting everything everywhere, giving rise to a challenging environment for companies. In fact, since 2000, 50% of the Fortune 500 companies have ceased to exist due to their loss of competitiveness as we continue through the era of digital disruption in what is known—according to the World Economic Forum—as the Fourth Industrial Revolution.

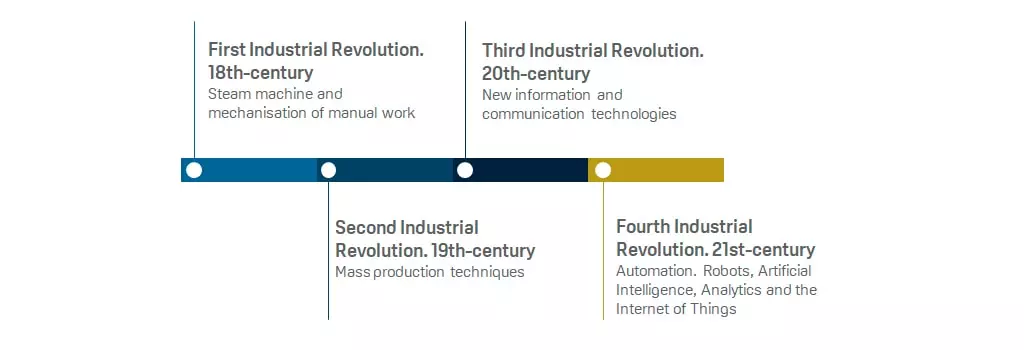

Let’s run through the First to the Fourth Industrial Revolution:

● First Industrial Revolution (18th century). Steam engines were used, making the mechanisation of textile factories and iron mills possible. Europe experienced a growth boom as people migrated from rural areas to cities in search of work.

● Second Industrial Revolution: (19th century). It was driven by electricity and supported by large-scale production and assembly lines, which led to work specialisation and cost optimisation.

● Third Industrial Revolution (20th century). Known as the beginning of the Information Age, it was characterised by the shift from analogue to digital technologies.

● Fourth Industrial Revolution (21st century). This stage is based on a new range of technologies fuelled by interconnectivity, such as robotic process automation, autonomous production, artificial intelligence, analytics and the Internet of Things.

What is robotic process automation?

The films Limitless (2011) and Lucy (2014) featured experimental drugs or smart pills that enabled the protagonists to continuously use 100% of their brains.

If we stick to the business sector, up to 80% of the work of a person can be described as based on rules that can be automated. Can you imagine a technology that could free teams from repetitive actions or processes that required no human decision or judgement? In this way, and without taking any smart pills, we could devote our brains and time to tasks that humans do best, such as those that call for judgement, communication, attention and critical thinking.

This technology already exists and is called robotic process automation (RPA). RPA is a robotic application that allows the automation of business tasks and processes with no human intervention in any department. Such as copying and pasting data, moving files and folders, reading and writing in databases, extracting data from websites, and many more. Have a look at that list below and see this technology’s potential:

It works 24 hours a day without interruption—except for maintenance and updates—with 100% precision while documenting all the work done, therefore increasing productivity, saving time, reducing costs, increasing reliability, and improving scalability and flexibility in order to—as mentioned earlier—adapt to actual needs and perform tasks with greater strategic value.

Robotic process automation: keys and deployment process

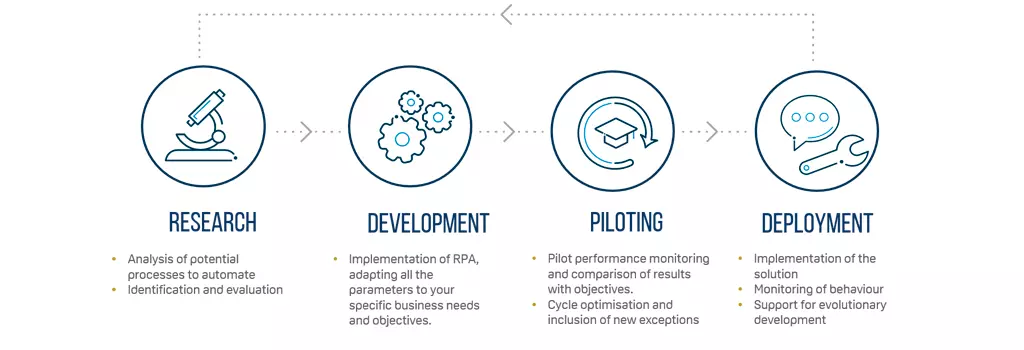

Robotic process automation has a very significant impact on companies and work at present, which translates into a high return on investment for the minimal impact its deployment has on the company, as it does not involve high costs, uses few resources and can be brought into service in a matter of weeks through these 4 phases:

Nevertheless, this doesn’t mean that there aren’t any keys or critical points to ensure that the deployment of robotic process automation is a resounding success. These are:

- Understanding that RPA is not a physical robot

- Its deployment does not alter the company’s infrastructure or apps

- Although an RPA software, as well as a hardware and IT infrastructure, is needed

- It requires careful research and planning

- It calls for collaboration and communication among all the stakeholders

- Document all steps and test everything

- IT participation and technical experience from the start

- And a maintenance and monitoring plan

Conclusion: are we open to change?

Now, more than ever, it’s crucial to be ready for new technologies such as robotic process automation that are a few years from becoming part and parcel of day-to-day business operations.

This is why companies must be open to change. Innovation doesn’t happen in a vacuum and whoever fails to innovate either gets left behind or ceases to exist—which is what has happened to 50% of the Fortune 500 companies since 2000.

The organisations’ scalability or ability to adapt plays an essential role in their competitiveness and own stability. The organisations that can adapt their technological and human infrastructure will reap the greatest benefits.

In this way, they will help usher in a new era: the Fourth Industrial Revolution.